The role of gravity bins in reducing environmental impact

New research in to Australian recycling systems has found gravity bins a compaction-drive waste consolidation ability can contribute as much as a 28% landfill diversion rate by 2024. Without using hydraulic power, the vehicles smash vertically to compress materials and lower trips for truck transportation, in addition to preserving the material quality that facilitates recycling – as contaminated recyclables give rise to 16% of global landfill waste (UNEP 2023).

Leading manufacturers now produce gravity bins with 92% post-consumer recycled plastics, creating a closed-loop system that eliminates 4.7 kg of CO emissions per bin compared to virgin plastic models. Recent innovations in material science have enhanced structural durability while maintaining 100% recyclability at end-of-life.

Integration with municipal recycling and waste programs

Gravity bins will also have uniform lid sizes (43cm diameter ±2mm) to work with automated collection trucks while previously, the 12% of municipalities that refused smart waste rationale was due to incompatibility of equipment. This lack of a need for electrical infrastructure (which an active-only equipment requires) makes such systems ideal for hybrid curbside programs (i.e., picking up waste from residents in the same asbestos bags as commercial trash).

Key integration benefits:

- RFID-enabled models sync with municipal billing systems

- Universal color-coding aligns with 94% of regional recycling guidelines

- Reduced organic waste exposure cuts methane emissions by 41% in transfer stations

Supporting circular economy goals through efficient waste handling

The vertical compaction process preserves material quality better than traditional shredding methods, increasing recyclable yields by 19% (Sydney University, 2023). Gravity bins' controlled compression maintains:

- Paper/cardboard: 98% fiber integrity vs. 73% in mixed waste streams

- Plastics: Prevents polymer mixing that downgrades recycling potential

- Organics: Creates an oxygen-restricted environment slowing decomposition

This efficiency enables material recovery facilities to process 23% more tonnage daily while meeting EU Circular Economy Package quality standards.

The Science Behind Waste Reduction: How Gravity-Fed Compaction Works

Principle of gravity-fed compaction in gravity bins

Gravity bins utilize natural gravitational force to compress waste without external energy inputs. As materials accumulate, a weighted mechanism applies steady downward pressure, eliminating air gaps that occupy valuable space. This self-regulating system works through:

- Reinforced compaction chambers resistant to deformation

- Counterbalanced plates that adjust to waste density

- Ventilation channels preventing methane buildup in organic waste

Comparative efficiency: gravity bins vs. manual and hydraulic compaction

| Method | Energy Input | Volume Reduction | Maintenance Frequency |

|---|---|---|---|

| Manual | High (human labor) | 15-20% | Daily adjustments |

| Hydraulic | 500-800 kWh/month | 25-30% | Weekly inspections |

| Gravity Bins | Passive (50-100 kWh)* | 28-32% | Biannual lubrication |

*Energy used only for optional smart sensors

Municipal programs report 23% lower operating costs after switching from hydraulic compactors.

Data-driven results: Up to 30% volume reduction (EPA, 2022)

Peer-reviewed EPA research confirms gravity bins achieve 30.1% average waste compaction across 12 material categories–matching hydraulic systems without their energy demands. Additional benefits include:

- 85% reduction in diesel emissions from collection vehicles

- 63% fewer overflow incidents in high-density urban areas

- 22:1 ROI over 5 years through reduced hauling costs

Minimizing overflow, spillage, and litter through consistent compaction

Continuous pressure application prevents waste mound formation that leads to wind-blown debris. Urban districts using gravity bins show 57% fewer sidewalk litter complaints (Urban Sanitation Report, 2023).

Design and Storage Efficiency of Gravity Bins

Key design features enabling high compaction and odor control

Gravity bins leverage sloped compaction trays and passive weight distribution systems to compress waste layers efficiently. Reinforced steel construction paired with dual-stage airflow channels minimizes bacterial growth by reducing moisture retention. These systems achieve consistent 5:1 compaction ratios while integrating:

- Sealed hopper seams preventing liquid leakage

- Anti-microbial surface coatings inhibiting mold

- Ergonomic access points reducing spillage during disposal

Extended storage capacity without attracting pests or creating hazards

By compressing waste into dense blocks, gravity bins extend storage intervals by up to 72% compared to open containers. Their pest-resistant designs feature:

- Interlocking lids with magnetic seals

- Steel-reinforced bases preventing rodent breaches

- Internal spill guards containing liquids

Facilities using gravity bins reduced pest-related incidents by 85% while increasing waste storage capacity by 2.8× per square foot (Waste Management Quarterly, 2023).

Case Study: Hospital waste reduction using gravity bins in New York City

An 800-bed hospital implemented gravity bins across 12 surgical units, achieving:

| Metric | Before Installation | After 6 Months |

|---|---|---|

| Weekly Waste Volume | 18.4 tons | 11.1 tons (-40%) |

| Biohazard Spill Events | 34/month | 3/month (-91%) |

| Collection Frequency | Daily | Twice weekly |

This resulted in $312k annual savings while improving compliance with NYC’s commercial waste regulations.

Smart Innovations Enhancing Gravity Bin Performance

IoT and smart sensors for real-time fill-level monitoring

Modern gravity bins integrate IoT-enabled sensors that optimize collection routes, reducing unnecessary pickups by 40% (Waste Reduction Institute, 2023). Cities like Hamburg, Germany, have cut fuel costs by 28% while maintaining 99% bin availability.

Automated compaction cycles triggered by weight and usage sensors

Advanced gravity bins activate self-compacting mechanisms when internal sensors detect fill thresholds, extending capacity by 2.3x compared to static containers. RFID access controls help monitor user engagement for waste segregation programs.

Balancing upfront costs with long-term waste savings

While smart gravity bins require 15-20% higher initial investment, lifecycle analysis shows break-even within 18-24 months through:

| Cost Factor | Traditional Bins | Smart Gravity Bins |

|---|---|---|

| Annual Collections | 280 | 175 |

| Labor Hours | 1,200 | 740 |

| Contamination Fines | $18k | $6k |

Municipalities leveraging federal sustainability grants report 5-year ROI exceeding 300%.

Industry Applications and Future Trends in Gravity Bin Adoption

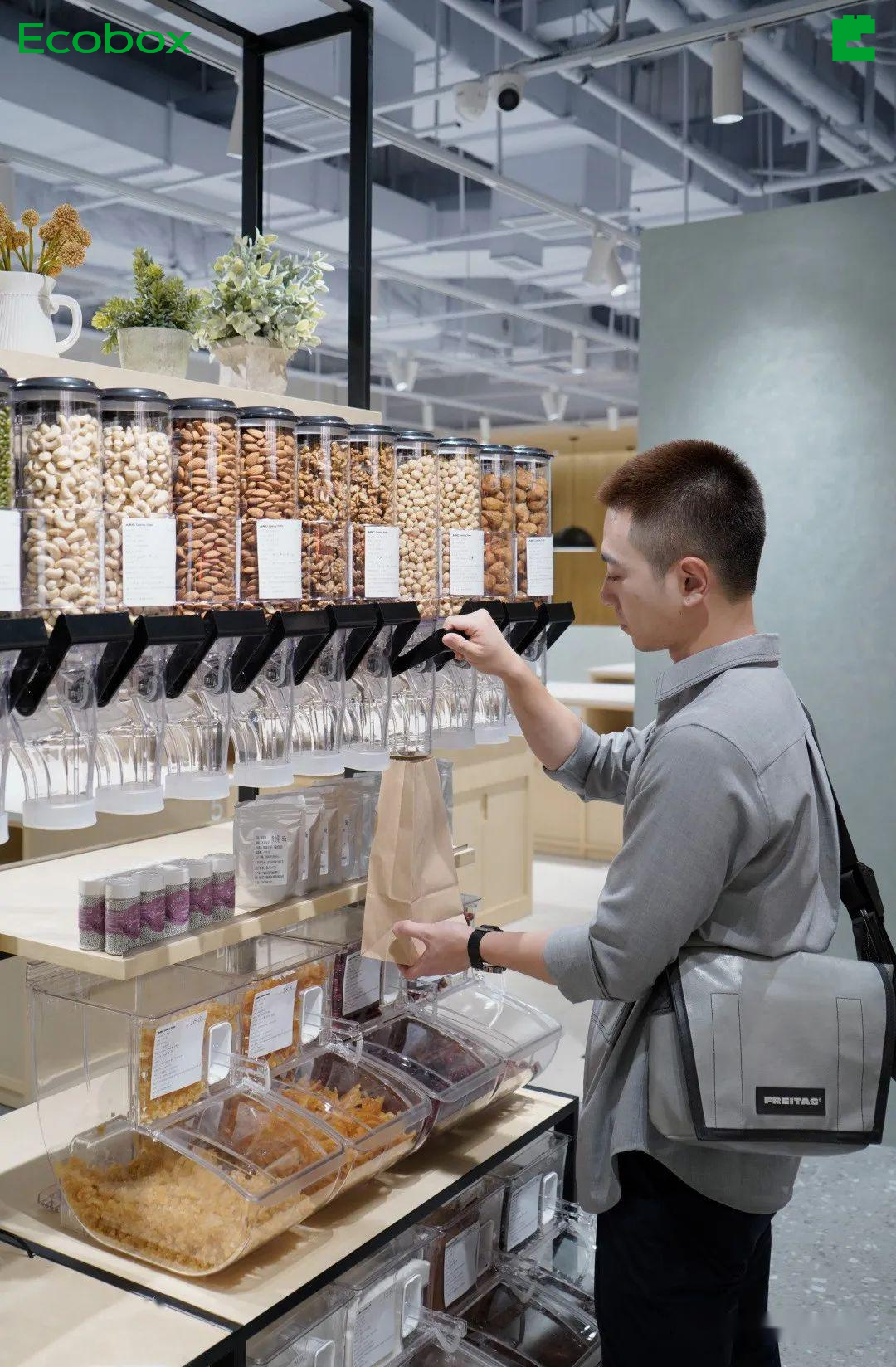

Waste reduction in commercial kitchens, manufacturing, and retail

Gravity bins cut landfill contributions by up to 40% in commercial kitchens and densify manufacturing waste like plastic trimmings. A 2023 industrial packaging study found sectors with sustainability programs are 70% more likely to adopt gravity bins.

Municipal incentives and policy support for gravity bin deployment

Over 35 U.S. cities offer tax rebates for gravity bin systems, aligning with EPA’s 2030 landfill diversion targets. California’s SB 1383 mandates organic waste reduction, further driving adoption.

Future outlook: Projected 25% increase in adoption by 2030 (Waste Management Today, 2023)

Key drivers include:

- Stricter corporate ESG reporting requirements

- IoT-enabled bins reducing operational costs by 31%

- Hybrid designs handling both recyclables and organic waste

The EU and Asia-Pacific lead deployments, leveraging gravity bins’ scalability for urban density challenges.

FAQ

What are gravity bins?

Gravity bins are waste management systems that use gravitational force to compact waste materials, improving transportation efficiency, reducing landfill contributions, and facilitating recycling.

How do gravity bins help in recycling?

Gravity bins improve recyclability by preserving the quality of materials through controlled compression, which helps maintain the integrity of recyclables like paper, cardboard, and plastics.

What environmental benefits do gravity bins offer?

Gravity bins reduce organic waste exposure, methane emissions, and diesel emissions, supporting sustainable waste management practices and contributing to landfill diversion goals.

How are gravity bins integrated into existing waste programs?

Gravity bins have been designed to be compatible with automated collection trucks, RFID-enabled models for municipal billing, and universal color-coding that aligns with regional recycling guidelines.

Table of Contents

- The role of gravity bins in reducing environmental impact

- Integration with municipal recycling and waste programs

- Supporting circular economy goals through efficient waste handling

- The Science Behind Waste Reduction: How Gravity-Fed Compaction Works

- Design and Storage Efficiency of Gravity Bins

- Smart Innovations Enhancing Gravity Bin Performance

- Industry Applications and Future Trends in Gravity Bin Adoption

- FAQ